What are the advantages of battery analytics over BMS?

What’s the difference?

|

In the realm of energy storage and electric vehicles (EVs), Battery Management Systems (BMS) and cloud-based battery analytics are two crucial technologies

that play distinct yet complementary roles. Think of them as the “airplane cockpit” and the “air traffic control tower” for your batteries. While the BMS takes charge of the immediate operations and safety of individual batteries, cloud-based battery analytics oversee the broader performance and health of an entire fleet of batteries. |

In this article, we will explore the key differences between BMS and cloud-based battery analytics and why they are both necessary to ensure the longevity and efficiency of battery systems.

Battery Management System (BMS): the Airplane Cockpit

The Battery Management System, often referred to as the BMS, can be likened to the cockpit of an airplane. Just as a pilot relies on the cockpit’s instrumentation and controls to monitor and manage the aircraft during a flight, the BMS serves as the nerve center for a battery pack. Here’s how the BMS works and why it is indispensable:

Cell-Level Monitoring: much like instruments displaying vital flight data such as altitude, airspeed, and fuel levels, the BMS continually monitors the individual cells within a battery pack. It checks voltage, temperature, current and estimates in real-time battery state of charge (SoC), and state of health (SoH).

Safety and Protection: the BMS ensures that the battery is being used within the manufacturer specifications. It prevents overcharging, over-discharging, and overheating: it is the last line of defense for catastrophic failures such as thermal runaway.

Cell Balancing: the BMS performs cell balancing to ensure that all cells within the battery pack charge and discharge evenly. This prevents capacity imbalances that can impact overall battery capacity.

Real-time Feedback: pilots rely on real-time data to make critical decisions during a flight. Similarly, the BMS provides real-time feedback to battery operators, allowing them to respond promptly to any issues that may arise.

Yet, BMS do come with certain limitations.

First and foremost, BMS settings are often static and rely on parameters set by the battery manufacturer during production. This means that BMS capabilities are constrained by the predetermined thresholds and control strategies, which may not be optimized for specific applications or evolving operational conditions. Additionally, a BMS is tailored to a specific battery chemistry and configuration, making it less adaptable when dealing with different battery types or chemistries.

Lastly, the computing capabilities of traditional BMS units can be limited, especially when compared to the advanced analytics and machine learning algorithms used in cloud-based solutions. This limitation can restrict the BMS’s ability to perform complex data analysis and predictive maintenance, which are increasingly important in modern battery management scenarios.

Hence, while BMS remains a vital component for battery monitoring, its capabilities can be enhanced and complemented by cloud-based battery analytics for a more comprehensive and adaptive approach to battery management.

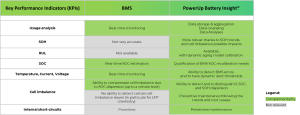

Figure 1. BMS and Cloud-Analytics comparative table

Cloud-Based Battery Analytics: the Air Traffic Control Tower

Cloud-based battery analytics can be seen as the air traffic control tower of battery management. It offers a broader, bird’s-eye view of battery performance and health across an entire fleet or system. Here’s why it’s essential:

Data Aggregation: like an air traffic control tower that tracks multiple planes simultaneously, cloud-based battery analytics gather data from various BMS-equipped battery packs. This aggregated data provides a comprehensive overview of an entire energy storage system or fleet of heterogeneous vehicles.

As an impartial and powerful tool, cloud-based battery analytics offers the ability to compare batteries from different manufacturers and chemistries.

Historical Analysis: battery analytics store historical data, enabling long-term performance analysis. This allows operators to identify trends, anomalies, and potential issues over time.

Predictive Safety & Maintenance: battery analytics can predict when maintenance or replacements are necessary based on historical performance data. This proactive approach reduces downtime and extends battery life.

Drawing upon a blend of battery electrochemistry knowledge and data expertise, it, on the other hand, guarantees predictive safety management of batteries. Battery analytics stands as the sole means to identify early indicators of battery failures that may eventually culminate in the dreadful thermal runaway.

Optimization: battery analytics use advanced algorithms to optimize the operation of battery systems. This includes accurate recalculations of battery state of charge (SoC), and state of health (SoH) to maximize energy efficiency and overall system performance.

BMS and Cloud-Based Battery Analytics: the ultimate monitoring combo

The comparison of a BMS to airplane cockpit and battery analytics to an air traffic control tower highlights their distinct but complementary roles in managing battery systems. While the BMS ensures the immediate safety and well-being of individual cells and packs, battery analytics take a more strategic approach, focusing on the broader health and performance of the entire battery ecosystem on the one hand; and its predictive safety on the other hand.

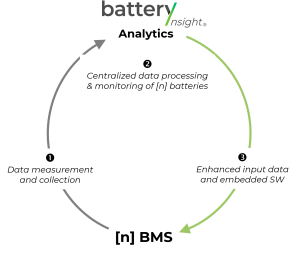

Figure 2. BMS and Cloud-Analytics synergies

Together, they form a powerful partnership:

Immediate Response and Long-term Planning: the BMS provides real-time feedback and immediate action, ensuring that any issues within the battery pack are addressed promptly. On the other hand, battery analytics help operators recalibrate their BMS and make informed decisions about the long-term safety and health of their batteries.

Preventative Measures: the BMS prevents real-time critical safety hazards, while analytics allow operators to proactively address maintenance needs before they become emergencies.

Data-Driven Decision-Making: both systems rely on data, but they use it differently. The BMS deals with real-time data for immediate action, while analytics utilize historical and aggregated data for strategic planning – both operationally and financially.

Conclusion: Battery Management Systems and Battery Analytics. What’s the difference?

While they have distinct roles, BMS and Cloud Battery Analytics work together seamlessly to ensure the safety, efficiency, and longevity of battery systems. Just as a pilot relies on a well-maintained cockpit and clear instructions from air traffic control, battery operators depend on both BMS and analytics to navigate the complexities of energy storage. This partnership is the key to unlocking the full potential of batteries, whether in electric vehicles, renewable energy systems, or any application where reliable energy storage is essential.

- Safeguarding Battery Storage: AI-Driven HVAC Anomaly Detection

- Time is money: The importance of fast and efficient battery analytics onboarding

- Resistance: a key – yet underestimated – parameter of BESS energy efficiency

- Battery Management System (BMS) vs Battery Analytics

- The challenges of evaluating State-of-charge (SoC) for battery assets