Understand how to use SoC

“The state of charge (SOC) of a cell denotes the capacity that is currently available (Q(t)) as a function of the rated capacity (Qn): SOC(t)=Q(t)/Qn”.

A cell State-of-Charge (SOC) can be defined as the available capacity remaining at a given moment as a function of its full capacity. In other words, it indicates how much energy is currently stored in the battery compared to how much the battery can hold when fully charged.

When talking about battery monitoring in field operations, the SOC indicator should be taken with caution. There are different ways to calculate and to display a battery SOC depending on one’s frame of reference.

In fact, battery systems’ manufacturers often give operators access to a revised SOC called “user SOC”. The user SOC is a displayed SOC that results from charge and voltage limitation strategies by the OEM to avoid in most cases overcharge or under-discharge. Displaying a user SOC instead of the actual battery SOC allows OEMs to avoid hence accelerated battery ageing but implies a constraining opacity level on the indicator displayed. Relying solely on user SOC does not provide operators with accurate information on the actual State of Charge of the battery over time. Knowing that the battery SOC level has a direct impact on its ageing, it is essential to have access to an accurate and representative SOC.

Why is it hard to accurately estimate SOC?

To estimate a battery SOC, most Battery Management Systems (BMS) measure its and the current charge / discharge flow rate. Though these measurements are likely to be consistent for SOC estimation under lab conditions, it is not accurate enough when it comes to actual field battery operation.

In fact, battery overall operation conditions – temperature, C-rate – need to be considered when estimating a battery SOC. In best-case scenarios, the SOC calculated by the BMS is based on basic coulometric SOC with saturations when the minimum cell voltage (correspondingly maximum cell voltage) reaches the minimum (or maximum) voltage thresholds at 0% and 100% – those thresholds being limited in case of user SOC (see above).

Since the SOC relates to a capacity calculated at given current and temperature, it would be more correct to take into account these two parameters, namely, the current rate and the temperature, in the coulometric calculation. In this case, it is essential to perform battery tests, at least at the beginning of life, in order to have a reference point and extract the cartography of the coulometric capacity as a function of the current rate and the temperature.

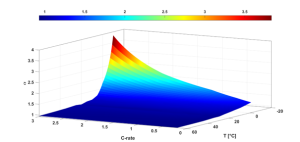

Figure 1. Alpha coefficient to calculate the available capacity of a given Li-ion cell according to C-rate and temperature.

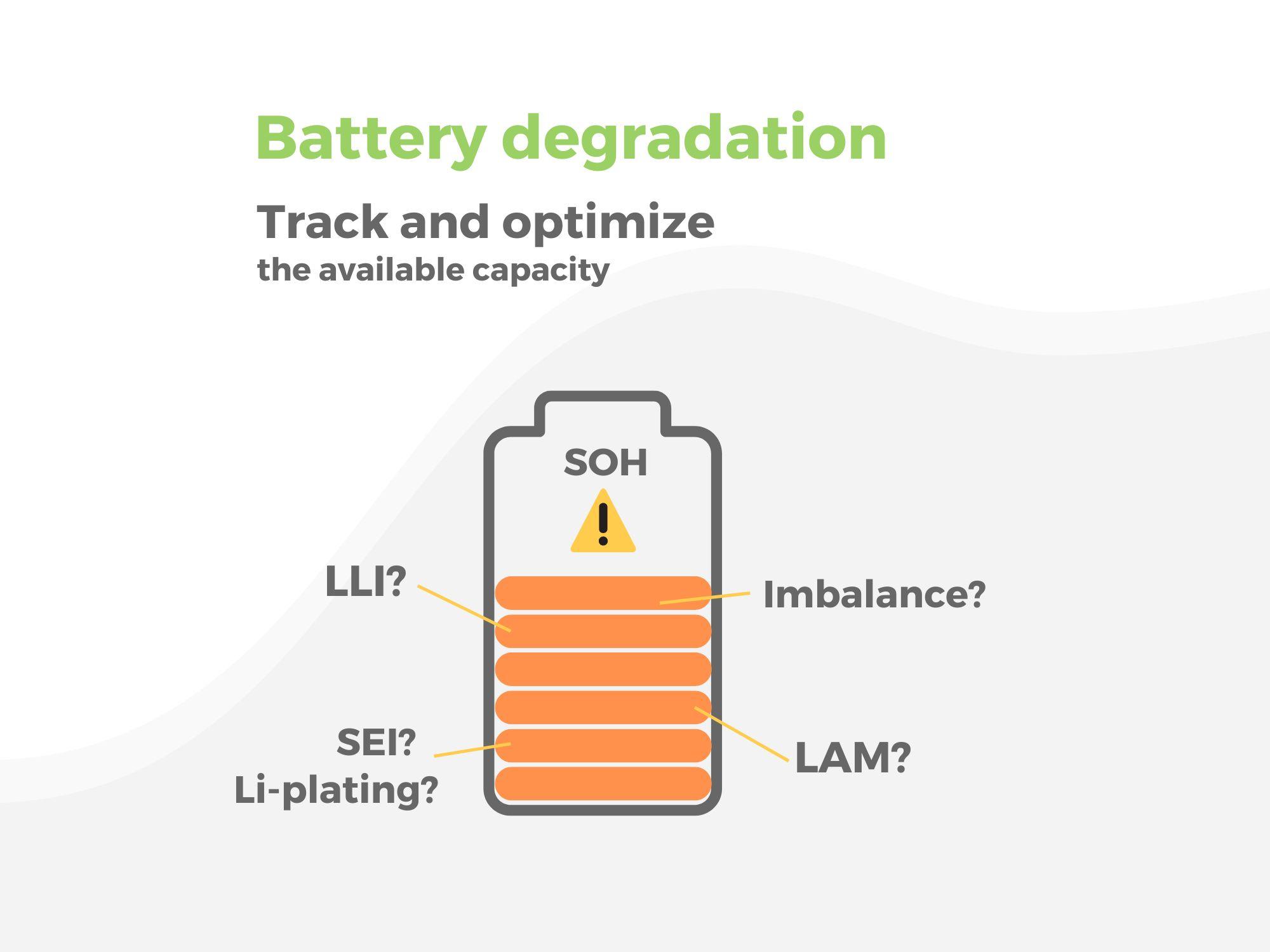

Moreover, SOC estimation is highly dependent on battery capacity measurement – State-of-Health (SOH). Even more so as a battery degrades with time and its capacity lowers: to accurately estimate SOC, you must first be able to have a reliable SOH measurement. It is therefore crucial to consider the actual capacity – based on the State of Health (SOH).

A reliable SOC would then be defined as function of SOH, Current & Temperature, SOC = f(Cref, I, T) with Cref = f(SOH).

Figure 1 shows the correction coefficient (Cref) allowing to get any capacity value – SOH – measured at a given temperature and current to a nominal condition. Nominal conditions being nominal temperature and Crate as defined by the battery datasheet – for instance T=25°C and Crate=0.5.

Cell-imbalance impact on SOC estimation

BMS should be able to monitor each cell voltage. Otherwise, in case of cell-imbalance, it is not able to cut off the charge or discharge when cell_volt_max reaches the maximum voltage threshold or cell_volt_min reaches the minimum voltage threshold (see above).

Unfortunately, if there is a significant cell imbalance within a battery pack, the limiting cells can impact the available energy. If the BMS does not take into account this imbalance – which is very often the case for SOH dispersion or SOC dispersion for LFP cells – the SOC indicator is enventually innacurate.

Read on LFP specifities compared to NMC

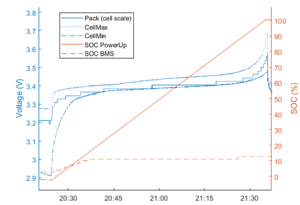

Figure 2. SOC deviation on an electric bus LFP battery pack

Figure 2. SOC deviation on an electric bus LFP battery pack

Figure 2 illustrates an extreme SOC deviation use-case on an electric bus. The accuracy of this SOC BMS has been significantly affected due to advanced ageing and cell-imbalance within the LFP battery pack. It can be observed that during a full, constant current charge, the SOC BMS varies very little, likely due to the limiting cells that have significantly reduced the available capacity in the battery. In this specific case, the BMS does not even proceed with coulometric SOC estimation. Otherwise, the “SOC BMS” curve would have had the same slope as the “SOC PowerUp” starting around 20:30. The cell-imbalance and lack of responsiveness of the BMS in this particular case eventually lead to a 75% SOC deviation.

Moreover, the BMS does not recalibrate the SOC to 100% when cell-volt-max exceeds its maximum threshold – 3.65V. All in all, cell-imbalance due to SOC dispersion and the potential overvoltage situation represent a critical safety risk that may lead to thermal runaway.

Understanding State-of-Charge (SoC): In a nutshell

SOC estimation in operation is a critical challenge that batteries operators must address to make the most of its performance. However, SOC estimation is a complex and multifaceted problem that required a deep understanding of battery chemistry, as well as advanced analytics tools and techniques.

- Relying solely on user SOC does not provide operators with accurate information on the actual State of Charge of the battery overtime. It is essential to have access to an accurate battery SOC estimation, in particular to assess the remaining useful lifetime.

- BMS can be helpless against a significant cell imbalance within a battery pack. In this case, without calibration, the estimated SOC is incorrect and the limiting cell impacts the available energy.

- A reliable SOC is to be defined as function of SOH, Current & Temperature, SOC = f(Cref, I, T) with Cref = f(SOH).

Still, there is no magic recipe to accurately estimate a battery SOC, different parameters need to be considered. We will tell you more in the coming articles on advanced SOC & SOH estimation methodologies.