Understanding battery capacity:

What are the key questions you should ask?

An average battery’s lifespan is in the range of 10 years. But will performance be consistent over its entire life? What developments can be expected?

Why is it trickier than expected to get an accurate estimate of a battery’s remaining useful lifetime?

What tangible upsides can reliable prediction tools bring?

In the dynamic landscape of battery technology, the reliability and performance of battery assets are crucial factors for developers and operators. Battery degradation, which encompasses the gradual loss of capacity and performance over time, poses a significant challenge. However, with the advent of advanced modelling tools, we now have the means to accurately predict and understand battery degradation, enabling us to optimize asset design, implement streamlined predictive maintenance strategies, and make informed second-life trade-offs.

In this article, we will explore the wide-ranging benefits of utilizing these tools.

From diagnosis to predictions

SOH (State of Health) and lifetime prediction are two distinct approaches that provide valuable information on a battery’s performance. SOH indicates the available capacity at a given moment – see article part 1 while lifetime prediction estimates the capacity at a future point in time.

The prediction of SOH is of utmost importance for several reasons:

Building a measured and sustainable asset

Battery degradation forecasting is not merely an option; it has become a necessity for developers and operators in the quest to build high-performance battery assets. These assets require a robust foundation that can withstand the rigors of real-world usage and deliver long-term value at the lowest initial CAPEX cost. Reliable prediction tools play a pivotal role in achieving these goals.

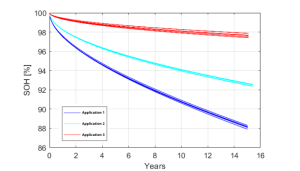

By employing advanced modelling tools, developers can optimize battery asset design parameters, select appropriate chemistries, and determine suitable operating conditions. Accurate predictions of battery degradation enable stakeholders to fine-tune their designs, to ensure optimal performance throughout the asset’s lifespan. With reliable prediction tools, developers can confidently bring their battery assets to life, knowing that they will meet performance expectations.

Figure 1. Remaining Useful Lifetime (RUL) predictions on different usage scenarios for asset design

Maximizing and extending asset lifespan

Predictive maintenance has emerged as a game-changer in asset management, allowing developers and operators to minimize downtime, optimize maintenance schedules, and extend the lifespan of battery assets. Advanced modelling tools are instrumental in implementing effective predictive maintenance strategies and making informed decisions.

When operated with granular battery data, these modelling tools will help detect accelerated ageing in individual modules or battery packs that can limit the performance of the asset as a whole. Additionally, this type of monitoring allows the detection of knee points, which refers to a sudden and significant drop of battery capacity. By accurately identifying knee points through simulation, developers and operators can proactively plan maintenance activities and prevent potential failures while optimizing the utilization of resources. Finally, they will make it possible to change the service mix during operations will clear knowledge about the impact on asset lifespan to continuously target the best compromise between usage and capacity degradation. Predictive maintenance reduces costs, enhances operational efficiency, and ensures that battery assets perform at their best for extended periods.

Figure 2. RUL simulation on different usage scenarios for asset optimisation

Empowering second life and asset monetization

Battery assets often have a significant amount of remaining lifetime even after their first use. As an example, the end-of-life (EOL) of an eBus battery comes when it reaches around 80% of its initial capacity. Repurposing batteries for secondary applications, such as energy storage systems or electric vehicle charging stations, presents an opportunity to maximize the value of the battery and minimize waste. However, making informed second-life trade-offs requires a deep understanding of battery degradation.

Advanced modelling tools provide crucial insights into the remaining capacity and performance of batteries after their primary life cycle. By simulating different operating scenarios, developers and operators can determine the feasibility and profitability of repurposing batteries for a second life instead of keeping the ongoing cycling application. This knowledge empowers decision-makers to make informed choices, optimizing the value and environmental impact of their assets.

Predictions, a complex art

While battery degradation simulation tools offer invaluable insights, it is important to acknowledge the challenges and limitations associated with their implementation. Developers and operators need to be aware of these factors to make informed decisions and set realistic expectations.

Physical models as first attempt

Developing accurate degradation prediction models requires a deep understanding of battery chemistry, physics, and electrochemical behavior. The first barrier is the knowledge of each of the battery components (electrolytes mix, additives, particles sizes, porosity) and how they were processed, which is heavily protected by the manufacturers. Batteries are deeply complex objects and even with this knowledge, it would be difficult to model every physico-chemical interaction.

However, it is possible to get good results with such physical models; some industrial software products are available in the market and provide quite satisfactory results. The issue is that the complex computation requires access to specialized testing facilities and expertise. In addition, the cost can become prohibitive when computations apply on long periods of time (counted in years for lifetime predictions) and on large assets, making it less interesting for fast-evolving field applications.

Empirical models can help

As a workaround, the evolution of battery performance is also inferred from aging tests campaigns where batteries are cycled in multiple standard conditions (T, SOC, I). Capacity is measured at different times during the tests and the results are used to calibrate empirical degradations law.

However, every type of cell follows a different aging path, and conducting a research campaign can be time-consuming and costly as they typically require test periods of more than a year. Moreover, the applicability of a cell’s degradation in lab testing to the pack and rack level during real operations poses its own challenges.

Advanced hybrid models are the answer

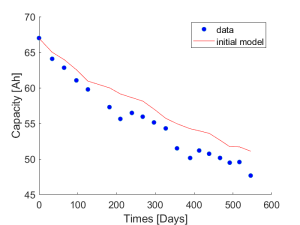

PowerUp’s solution is based around a number of ”reference cells” that we have studied extensively and are representative of the Li-ion battery family. The model we derived from test campaigns are used as a first sketch which is then refined during each SOH estimation via a stochastic approach. Every new data point is used to continue developing the prediction and to enrich it with statistical indicators.

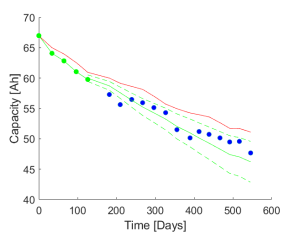

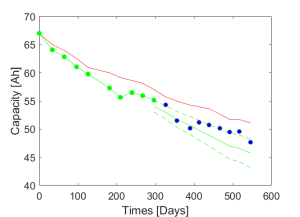

Figure 3. RUL stochastic correction based on monitoring data

The use of this iterative loop facilitates a better fit of the prediction to the actual cells used in the asset and allows us to take into account for the wide range of system architectures. After the models are properly calibrated on each asset, we can then provide predictions on the battery performance given different operational scenarios.

In parallel, we are continuing to develop a growing database of references which feeds machine learning models in order to be able to predict the remaining lifetime of cells. These predictions enhance our traditional approach and encompass all the experience we have with numerous data sets on different types of operations to ensure a faster and more reliable forecast.

The diagnosis and prediction of battery capacity: conclusion

As we venture into the future of energy storage, embracing the potential of battery degradation simulation is essential. By harnessing the power of advanced modelling, we can unlock the full potential of battery assets and pave the way for a greener and more efficient world.