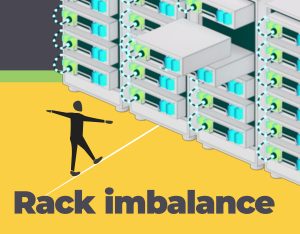

Don’t let one imbalanced, poorly performing rack determine the efficiency of a whole container.

| Rack imbalance, just like cell imbalance in a module, can limit the available energy for dispatch in a BESS and even lead to more serious problems in the long-term. New functionality recently introduced in Battery Insight® will drive you straight to an imbalanced rack and even guide you to a practical resolution, saving you time and money and protecting your battery assets and revenue streams. |  |

Introduction: Understanding rack imbalance

When it comes to batteries, there are many possible causes of performance degradation. There are external causes linked to the use of energy storage infrastructure (for example, the intensity of energy demand peaks) and the operating conditions in which batteries are used (for example, very high or very low temperatures). In the case of stationary storage systems (BESS), there is another aspect that needs to be considered with just as much attention:

- The imbalance between the cells making up the lithium-ion battery racks, or “intra-rack” imbalance,

- The imbalance that can occur between battery racks connected to the same inverter (known as a PCS for Power Conversion System), or “inter-rack” imbalance.

This article focuses on scenarios where imbalances occur among interconnected racks linked to an inverter (which converts, regulates, and distributes voltage). Some racks may experience significantly heavier usage for energy storage and distribution, or have differing State of Charge (SOC) estimates. Such imbalances inevitably impact negatively on infrastructure performance, potentially leading to revenue losses for system operators.

For more information on cell balancing in a lithium-ion battery, which aims to ensure that all cells in a battery pack operate at a similar voltage level, please refer to the technical article previously published in Battery Knowledge: Focus on cell imbalance – Predictive safety management

How can BESS rack imbalances be detected early and corrected?

Malfunctions leading to rack imbalance

Disparities between racks can result from differences in capacity, resistance, or SOC. Specifically for SOC, the issue may stem from actual SOC disparities or just estimation errors, both of which hinder optimal asset management. Depending on the imbalance’s cause, several malfunctions can occur. Initially, this primarily results in a loss of performance where energy is unevenly used, poorly utilized, or even wasted. This can escalate to a rack failure (reversible or not) if a rack goes out of service, cutting off the power supply and causing both significant inconvenience as well as . It can also create serious operational issues if the BESS is then unable to meet energy dispatch demands.

Poor performance and service life: the impact of rack imbalance.

To address this, different levels of the Battery Management System (BMS) continuously monitor the voltage of all BESS modules and rack stages to identify such malfunctions, both at module and rack levels. This monitoring is crucial because discrepancies between racks can stem from differences in capacity, resistance, or State of Charge (SOC).

The consequences of these imbalances between racks connected to the same Power Conversion System (PCS) fall into two main categories:

- Total disconnection of all racks connected to the same PCS, the worst-case scenario

- Disconnecting the affected rack and continuing to discharge the remaining racks. This minimizes the impact but still results in uneven usage between racks as well as a reduction in energy due to the disconnected rack. This can lead to uneven aging* and the additional issue of a reduced usage lifetime for the BESS as noted below

- Reduced usage Lifetime: The “rotten apple in the barrel ”, the imbalances caused by just one affected rack cause uneven aging across all racks in the container*. Consequently, the entire container’s service life degrades, ultimately limited by the performance of the “weak links in the chain”: its weakest racks.

*Uneven aging is the result of variations between different SOC rack profiles as well as differences in other variables such as temperature and current.

A marriage of deep expertise in electrochemistry and data science: How PowerUp identifies and resolves rack imbalance

When considering these explanations, it is easy to understand how important it is to quickly detect these imbalances, which undermine the energy performance and lifespan of racks and modules and directly impact the revenue generated from their operation. With this in mind, Battery Insight®, PowerUp’s advanced battery analytics cloud platform has been further improved with an important new feature .

PowerUp’s powerful battery analytics software now triggers an alarm when an imbalance is detected between racks, and also between racks connected to the same PCS. Furthermore, the battery analytics software platform will also provides the maintenance actions required to resolve the issue(s), via Battery Insight’s® “Recommendations Functionality”

This new feature is included in all Battery Insight® performance packs dedicated to BESS applications and has only been made possible as the result of a very specific combination of technological expertise. To increase the sensitivity of imbalance detection and determine the root cause more quickly, PowerUp has developed this powerful methodology by combining its teams’ expertise in battery electrochemistry and data science. These strengths accelerate the identification and resolution of anomalies and better preserve asset performance and lifespan, as well as associated revenues.

Case Studies: Battery Insight® in Action

Case Study 1: SOC Gauge Dispersion

In this example, the State of Charge (SOC) gauge of the battery racks drifts over time, obscuring the true SOC. Our case study clearly demonstrates Battery Insight®‘s algorithm’s ability to detect this drift from its inception. In circle one, we see the start of SOC deviation between the different racks. And in circle two we see a perfectly balanced profile after calibration (the different SoC profiles have overlaid on one another creating “solid blocks” on the graph). This early identification enables the application of timely and appropriate maintenance actions. In this specific scenario, the solution is a straightforward re-calibration of the gauges across the various racks connected to the Power Conversion System (PCS).

Case Study 2: Actual SOC Dispersion

In this second example, the SOC deviation between racks connected to the same PCS represents a genuine imbalance problem, extending beyond simple gauging issues. Once again we see a distinct deviation in the SOC profile. However, this time because the drift is far more evident as it is due to actual imbalance rather than any issue in gauging.

This case study illustrates how Battery Insight®’s algorithm effectively detects this deviation from the outset, immediately linking it to the necessary maintenance action: adjusting the imbalanced rack’s SOC level to match the others.

If you would like a demonstration of Battery Insight® please contact us by clicking here.