Essential to ensure the optimal performance of your BESS – but also an important part of warranty management, adherence to nominal operating conditions is an intrinsic part of battery asset management. This article explains the importance of respecting nominal conditions and how Battery Insight® can facilitate this process, protecting your assets, reducing cell degradation and stopping revenue leakage (whilst keeping your insurance underwriter happy!) |  |

Part one.

Understanding the importance of nominal conditions.

Nominal conditions (sometimes referred to as the “operating envelope”) are put in place by manufacturers to define the optimal parameters for the safety, efficiency and longevity of batteries. These strict, contractually defined parameters set the conditions for which a battery system is expected to perform efficiently and safely. Nominal conditions are the “Factory Settings” on a complex machine. They are the parameters the manufacturer determined were the perfect baseline: not too hot, not too cold, not too fast. They represent the established starting point that is proven to work. They are the “sweet spot” which when hit, will ensure the BESS works most safely and effectively on a short and long-term basis.

Make sure you stay on top of nominal conditions for safety reasons and proof of responsibility.

Battery manufacturers play the lead role in defining nominal conditions, but insurance companies will carefully evaluate them, as they in the end, must pay the bill if things go wrong.

Two types of warranty will be commonly made available to BESS operators:

- Manufacturer guarantees (warranty): The performance warranty will guarantee the battery systems’ State-of-Health for a specified period (often between 10-15 years) uniquely on condition that the operator adheres to the pre-defined nominal conditions

- Insurance (covers catastrophe and external forces): BESS are treated as high-risk assets, primarily due to the risk of safety incidents linked to thermal runaway and fire. Positive proof of adhering to nominal conditions can help battery asset managers secure lower premiums. Similarly, in the event of a safety incident, the operators respect of nominal conditions will be scrutinized as part of any potential claim.

It is important to note that insurers will also heavily scrutinize the warranty a BESS project has put in place. A strong manufacturer warranty reduces insurer risk, potentially leading to more favourable terms for the Battery Asset Manager.

Respecting nominal conditions is therefore a prerequisite for battery asset management.

What are the key nominal conditions?

- Temperature range

- Voltage range

- C-rate (current normalized to nominal capacity) or Power-rate

- State-of-Charge (SOC) range

You can find a detailed overview of nominal conditions for this article, including definitions for each one at the end of this article (Annex two).

General conditions and warranty criteria: What’s the difference?

General usage and warranty management

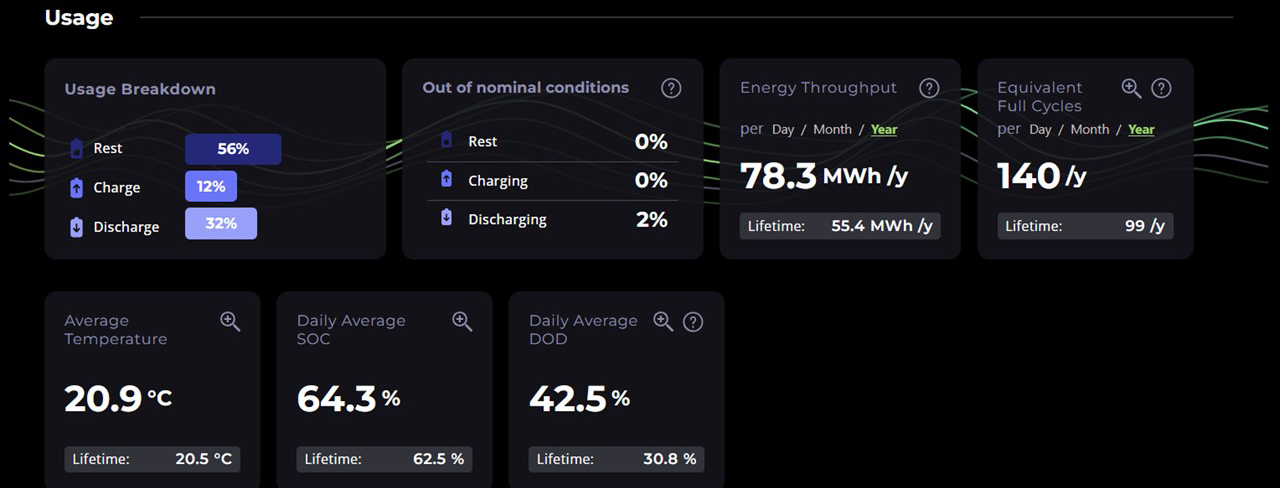

Battery Insight® provides reporting data for operating conditions using KPIs such as usage breakdown, energy throughput, number of full equivalent cycles, average temperature, average SOC, and average DOD, which are calculated automatically for the selected time (either the entire asset history or a specific time bracket).

|

Figure 1: Monitoring general and nominal conditions with Battery Insight’s® Usage and Warranty management dashboard – see annex one for more information |

Managing and tracking general and nominal conditions on Battery Insight® is simple. Metrics for nominal conditions are included with KPIs for all operating and nominal conditions on the same intuitive dashboard.

Part two.

Don’t let the sweet spot turn sour: Managing out of nominal conditions.

Battery Insight® calculates operating conditions that fall outside the expected limits during charging, discharging, or resting states, and presents details of this information visually, through heatmaps. You can see this tile above in Figure 1.

In simple terms this means that you have all the information you need, clearly communicated on one intuitive interface to ensure that you stay in the “sweet spot”.

Heatmaps: A visual retrospective of adherence to nominal conditions

Track critical nominal conditions for charging/discharging with just a quick glance in Battery Insight’s® heatmaps

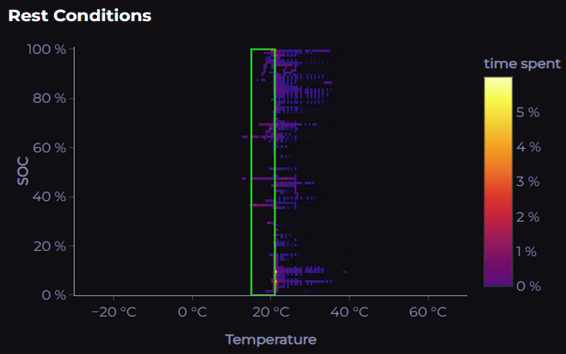

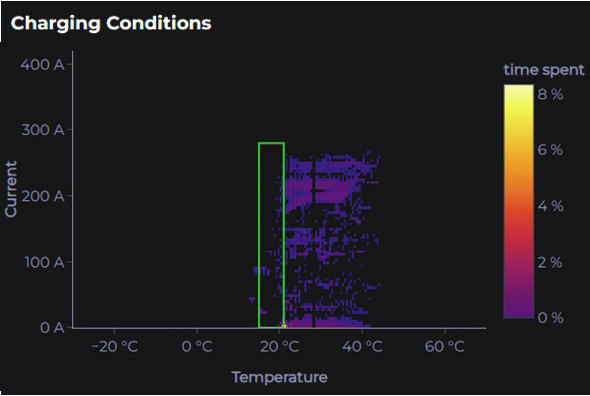

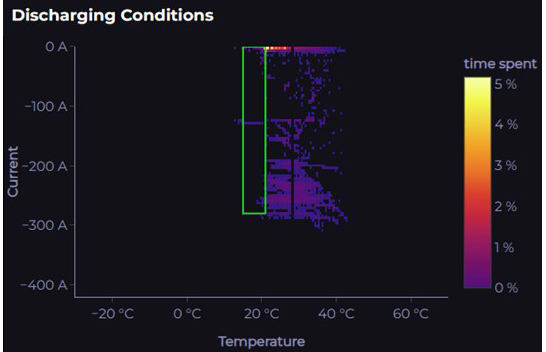

Heatmaps are a visual representation, within Battery Insight®, of the operating envelope for Charge/Discharge and Rest. These are useful to BESS operators because they enable the monitoring of real usage conditions, quickly and easily. They visualise battery rest, charge and discharge cycles and enable the Battery Asset Manager to quickly compare this data with the predefined usage conditions (nominal conditions). These settings can be easily modified by the users, and the calculations are then automatically updated.

Figure 2: Overview of out of nominal conditions metrics for three modes: Rest/charge/Discharge | An initial dashboard illustrates the current state of the modules with reference to nominal conditions across three areas: rest, charging, discharging. |

Figure 3: Battery Insight® heat map indicating no metrics out of nominal conditions | By clicking on each level (rest/charge/discharge) the user can then deep-dive into a new level of information for each mode. In the image to the left (a Battery Insight® screengrab) we can see the relationship between State-of-Charge and Temperature over time, in relation to nominal conditions. Each pixel is graded in a colour representative of its time spent in a given condition. By hovering the mouse over the graph, the user can identify the time spent at a given temperature and SOC of each specific area of the heatmap. |

The green frame around the outside of the heatmap denotes the nominal conditions in which the batteries are allowed to operate. The result is a comprehensive overview of rest cycle conditions relative to the battery manufacturer’s operating envelope.

This analysis can be further refined by choosing the time-period required for the analysis: Six months/1 year/2 years/5 years/10 years/Full life of module, or a defined period determined by a start and end date.

In this instance, we can see clearly that there are no issues. The batteries have not breached their nominal conditions and there are no outliers.

In Figure 4. for discharging batteries, the heatmap illustrates the discharge current (in Amperes) and the C-rate versus temperature. As above, the green rectangle denotes the nominal conditions. We see again that the batteries are performing as expected with no breach of the nominal conditions. | |

Figure 4: Nominal charge/discharge heatmap within effective operating envelope for discharging battery |

Automatic detection of overruns: What to look for?

What you see when a breach of nominal conditions occurs.

Use case #1: Current overruns.

Figure 5: Global overview of rest/charging/discharging cycles for out of nominal conditions | The Global Overview, the initial metrics shown on Battery Insight® clearly indicates that while the BESS is performing effectively during rest and charging cycles, there are clear issues in relation to nominal conditions for the discharge cycle. The discharge cycle is performing 23% outside nominal conditions. |

Figure 6: C-rate discharge out of nominal conditions | With just one click, the battery operator can bring up the heatmap to view a macro analysis of the batteries’ discharge performance. Figure 6 illustrates that the C-rate in discharge should be limited to C/4 (0.25C) when it does, in fact, reach 0.35C. While this difference may be considered insignificant in terms of usage, it may contravene the cell manufacturer's warranty. |

Use case #2: Rest/Charge/Discharge – Extreme temperature overruns

| The optimal operating temperature range for the BESS discussed in this use case is 15°C–21°C. Figure 7. visualizes actual BESS usage illustrating significant temperature overruns. The heatmap clearly shows that the temperature has exceeded the safe perimeter defined by the manufacturer’s nominal conditions by some clear margin. Additionally, the BESS Asset Manager would have breached any performance or safety warranty put in place nulling any performance or safety contract. |

| |

Figure 7: Extreme overrun of BESS temperature for rest/charge/discharge cycles |

Part three.

RUL breaking: The long-term impact of breaching nominal conditions.

Exceeding nominal conditions can have a detrimental impact on BESS lifespan and contravene contractual warranty obligations. What to look out for…

In this last chapter we will look at different profiles for overruns of temperature, using the example of case studies two and three in the previous section, to illustrate the very different results for Remaining Useful Life that can arise from each one.

The overruns of nominal conditions illustrated in this article are important for two reasons:

- Operating BESS outside its optimal operating conditions can have a long-term impact on cycling aging (degradation from use) as well as calendar aging (degradation over time). This can affect BESS operators or owners’ ROI (long-term business planning) as well as result in diminishing revenues in the medium to long-term.

- Overruns observed in the field, while sometimes viewed as insignificant in operational terms, may risk penalizing the suppliers’ (or the insurance underwriter’s) guarantee.

Results show the degradation-aware strategy can extend battery lifetime by 5–8 years and improve net present value and internal rate of return over a 15-year period compared with traditional methods. These findings highlight the economic benefits of flexible, degradation-aware operational strategies and suggest that more adaptive warranties could accelerate renewable energy integration and lower costs for storage operators.”

Degradation-Aware Derating of Lithium-Ion Battery Energy Storage Systems in the UK Power Market

(MDPI peer-reviewed report)

According to research conducted by PowerUp, the long-term effect on RUL (Remaining Useful Life) caused by overruns on nominal conditions is variable. The effect of breaches of nominal conditions is not clear-cut; cell degradation will vary depending on the type of breach of nominal conditions.

This research demonstrates that certain excesses of these conditions, however slight, can have an impact on the battery lifetime (see Figure 11 below). Conversely, other infringements of the operating envelope, even repeated ones, will have no long-term effect on cell degradation. In practical terms, a clear understanding of these dynamics will take the idea of the “sweet spot” one level higher with access to data that can identify a “Peak Performance Zone” – a potentially game-changing new means of managing BESS.

Through a greater understanding of these profiles, BESS operators will be able to move from a “black and white” dynamic, with reduced margins of operability for battery assets, to one where operational nuance is available; effectively presenting new options to operate BESS while potentially reducing cell degradation and extending BESS lifetimes.

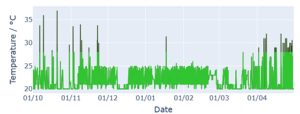

Example 1: Acceptable breaches of nominal conditions

In Figure 8. above, we see temperatures analyzed with Battery Insight® over a period of six months. The in-nominal condition temperatures are marked in light green and the out-of-nominal condition temperatures are marked in dark green.

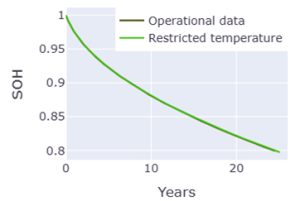

The figure below shows RUL simulation for actual use (dark green) and recommended use light green.

In this example, the observed temperature overruns do not influence the aging process.

*Note: Such is the adherence to nominal conditions in this example, that operational data and the nominal condition here (temperature) overlap. This is why the dark green line is not visible. In short – the battery asset manager has hit the sweet spot.

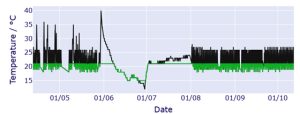

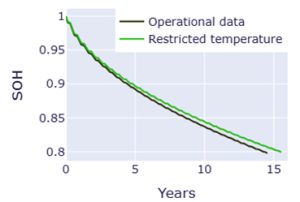

Example 2: Unacceptable breaches of nominal conditions

The figure below shows actual field temperatures in dark green and the recommended range in light green:

The figure below is a RUL simulation illustrating actual use (dark green) and recommended use (light green):

Conclusion: Managing nominal conditions

Adhering to nominal conditions is paramount for effective battery asset management. By rigorously maintaining the specified temperature, voltage, current, and state-of-charge parameters, operators can ensure optimal performance, maximize cycle life, and maintain the safety and reliability of battery assets. As a cornerstone of battery asset management, it is also essential to ensure that all contractual obligations for both safety and performance related warranties are met.

Consistent adherence to these conditions minimizes degradation, reduces the total cost of ownership, and solidifies the battery’s role as a dependable component within any system. Proactive management based on nominal conditions is more than just best-practice; it’s a fundamental requirement for realizing the full potential and longevity of valuable battery assets.

Battery Insight® is a battery analytics solution fully-equipped to manage these conditions – through a range of powerful, analytic monitoring tools available for both quick daily checks and high-granular deep-dive analyses.

If you would like to find out more, or would like a demonstration of Battery Insight®, contact us by clicking here.

Further reading: Annexes

Annex one: Additional criteria relevant to nominal conditions, insurance and warranties (Cycles, SOC and temperature)

A wide range of metrics are available on Battery Insight®, in addition to the heatmaps previously discussed, to help you manage your BESS and ensure that your energy storage system stays within the “sweet spot” defined by the manufacturer’s nominal conditions.

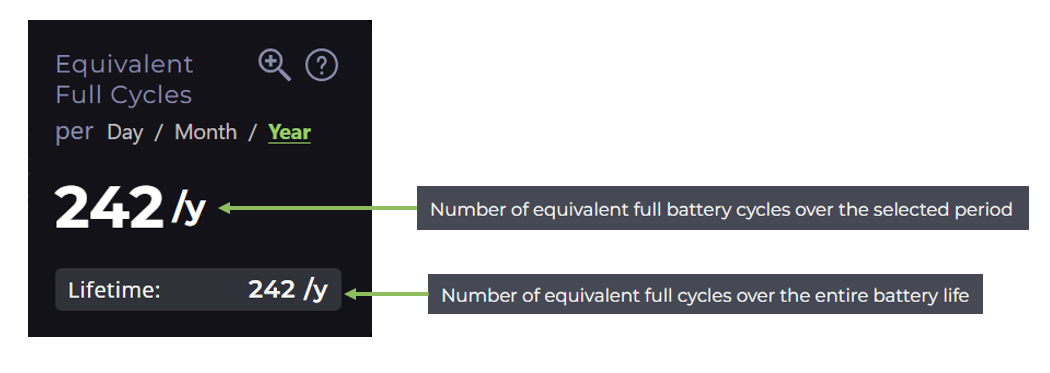

| Equivalent full cycles Battery Insight® computes the number of complete battery cycles over the selected period* and displays this per day, per month or per year. This means you can quickly take stock of the intensity of your battery usage.* Six months/1 year/2 years/5 years/10 years/Full life of module, or a given specific period. |

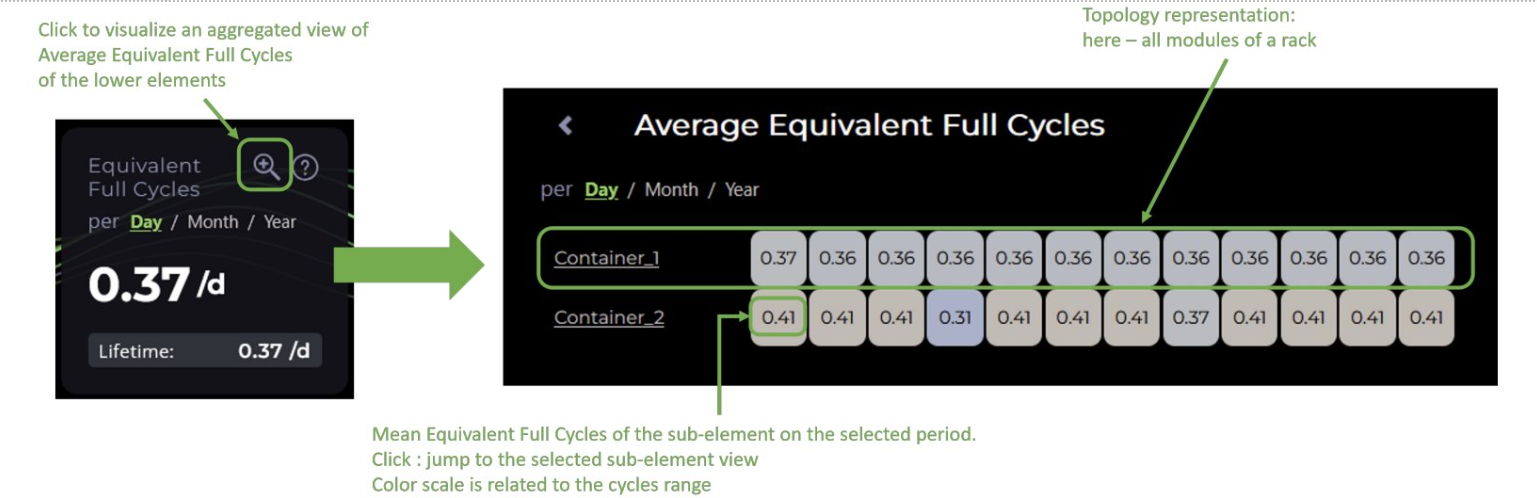

| You can even drill down into more detail by analyzing this performance at the next level, with KPIs for equivalent full cycles for all modules within a rack. |

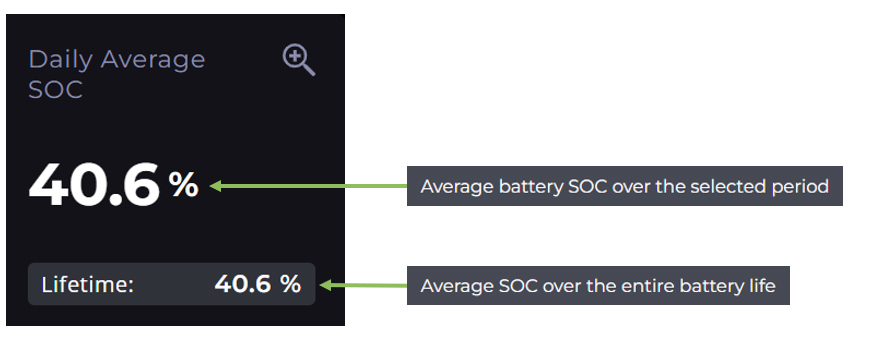

| Daily average State-of-Charge You can monitor your daily average SOC, in an instant, to check compliance with nominal conditions. |

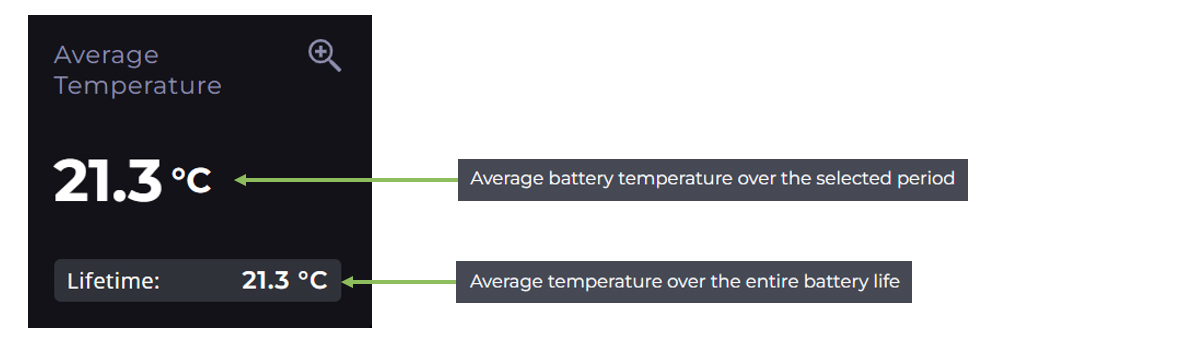

| Average Temperature If you don’t need the details offered to you by the heatmap and just want to understand the average temperature of your BESS, racks or modules on-the-fly, this information is also available. |

Definitions of nominal conditions: Annex two

Nominal condition | Importance |

Temperature Range: The optimal ambient and cell temperature often cited as being in the range of 15-35°C for lithium-ion batteries (BESS) this range is wider for electric mobility applications. | Breaching these conditions increases the risk of chemical degradation and irreversible capacity loss. High temperatures are a primary contributor to thermal runaways. |

Voltage Range: The safe minimum and maximum voltage levels for charging and discharging. | BESS voltage ranges are narrow. Over voltage can lead to thermal runaway directly, or to lithium-plating, potential short circuits and ultimately thermal runaway. Undervoltage can lead to permanent and severe loss of capacity. |

C-Rate (current normalized to nominal capacity): The specified charge and discharge current rate relative to the battery's nominal capacity. | The C-rate is a primary factor in the rate of battery degradation, and as such, a crucial parameter in the manufacturer’s warranty. A high C-rate can result in increased heat generation and a risk of thermal runaway. It further increases the risk of lithium-plating and ultimately short-circuit and/or thermal runaway. This limitation can also be expressed in terms of power-rate, i.e, the rated maximum power for charging and discharging. Like current, it is essential for the safety, longevity, efficiency and reliability of the BESS. |

State of Charge (SOC) Limits: The recommended minimum and maximum SOC (e.g. 5% to 95%). | SOC is often referred to as “What’s in the tank”. If SOC is “what’s in the tank”. The SOC limit refers to how much you can leave in, or empty that tank, safely. As for voltage, there are strict safety limits that must not exceed SOC=100 or drop below SOC=0. Additional restrictions may sometimes be applied to help extend the battery lifespan.

|